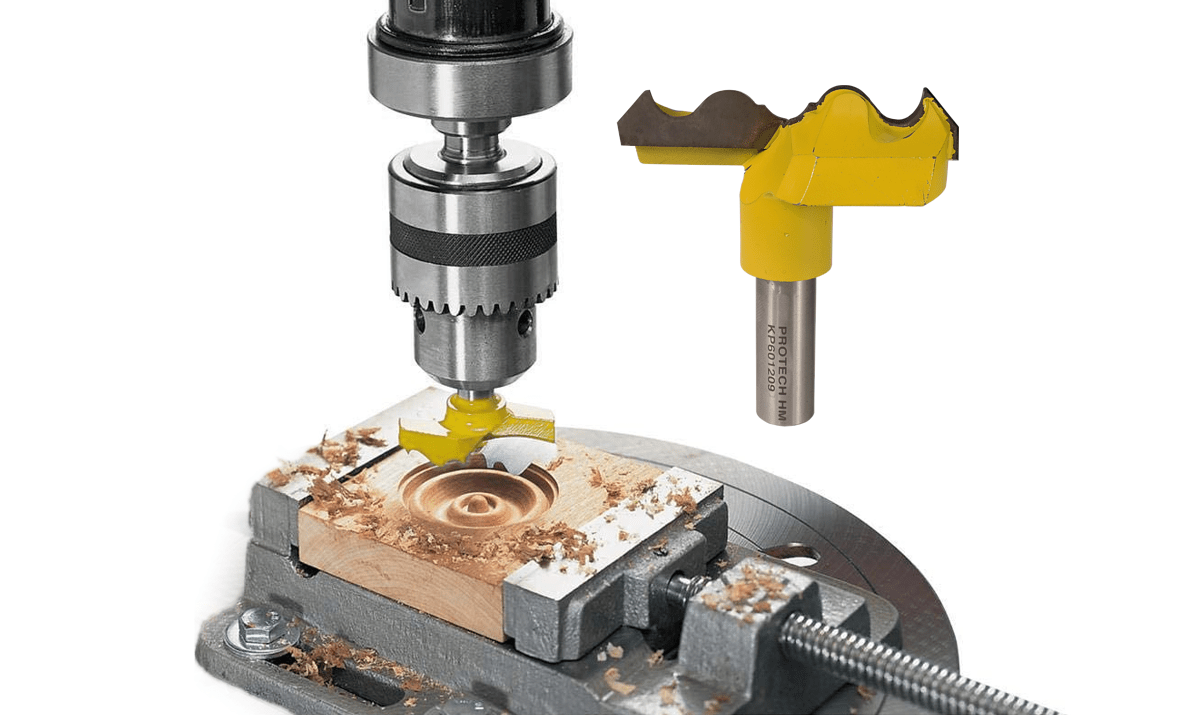

A Guide to Using Rosette Cutters

Perfect for furniture, home building and restoration. For a smooth finish in stubborn hardwoods, dampen the surface of the wood with a sponge just prior to the last cut. These are CARBIDE TIPPED cutters intended for use in a drill press.

SAFETY NOTE: NOT INTENDED FOR ROUTER USE. This product is designed to be used in a variable-speed drill press or lathe at less than 600rpm. All material must be securely clamped to prevent injury or damage to the project. Never use in a hand drill or router.

Cut the blocks to size on the table saw after making all the rosettes.

Using a rosette cutter is not difficult, but it takes a little getting used to because they are fairly large and sort of intimidating at first. Cut the blocks to size after making all the rosettes. Take the blank over to the table saw and cut the individual rosette blocks down to the final size.

- Clamp it down: Clamp the workpiece securely to drill press table

- Use a long blank: To make rosette blocks, cut several rosettes in a long blank. The extra length allows you to clamp the blank securely to your drill press table.

Setup

To start with, you should always make sure your workpiece is firmly clamped to the drill press table. Rosette

cutters don't have a center point to guide them. Because of this, they tend to grab the wood as they cut. If you

try to hold the workpiece by hand, or if you don't have it securely clamped down, the cutter will grab it and

fling it off the drill press table.

To start with, you should always make sure your workpiece is firmly clamped to the drill press table. Rosette

cutters don't have a center point to guide them. Because of this, they tend to grab the wood as they cut. If you

try to hold the workpiece by hand, or if you don't have it securely clamped down, the cutter will grab it and

fling it off the drill press table.

Trying to clamp a small block of wood down to a drill press can be a challenge. So if you're making square rosette blocks (like for trimming out a door or window), you'll find it easier to cut the rosettes in a longer piece of stock first and then cut the individual blocks to size

Speed

In addition to holding the workpiece securely, the other thing you'll need to pay attention to is the drill press

speed. Carbide-tipped rosette cutters can be run at medium to high drill press speeds — 2000 to 3000 rpm. Although

most cabinetmakers will tell you to use it at speed maximum of 600rpm, it is necessary to do test cuts. The type of

wood will indicate what speed is required. A slightly cleaner cut will be obtained when using higher speeds -

therefore a test cut is required.

In addition to holding the workpiece securely, the other thing you'll need to pay attention to is the drill press

speed. Carbide-tipped rosette cutters can be run at medium to high drill press speeds — 2000 to 3000 rpm. Although

most cabinetmakers will tell you to use it at speed maximum of 600rpm, it is necessary to do test cuts. The type of

wood will indicate what speed is required. A slightly cleaner cut will be obtained when using higher speeds -

therefore a test cut is required.

Chatter

Aside from all the safety issues, the real challenge when using a rosette cutter is getting smooth results. Despite their name, rosette cutters actually do more scraping than cutting. Because of this, it is common to experience some chatter when using one. If this happens, back off on your feed rate a bit to take a smaller cut.

Because the rosette cutter is travelling in a circular motion, you can't avoid cutting through at least some end grain. If you are working with an open-grain wood like oak, some tear-out is almost inevitable. Tighter-grained woods like maple and cherry seem to yield better and smoother results. But no matter what type of wood you use, plan on doing a little bit of sanding to clean up any rough spots, particularly on the end grain.

Cutting to size is the last step

After

making all the rosettes, take the blank over to the table saw and cut the individual rosette blocks down to final

size.

After

making all the rosettes, take the blank over to the table saw and cut the individual rosette blocks down to final

size.

Note: Holding small pieces of wood on the drill press table while using such a large diameter cutter

is not safe!