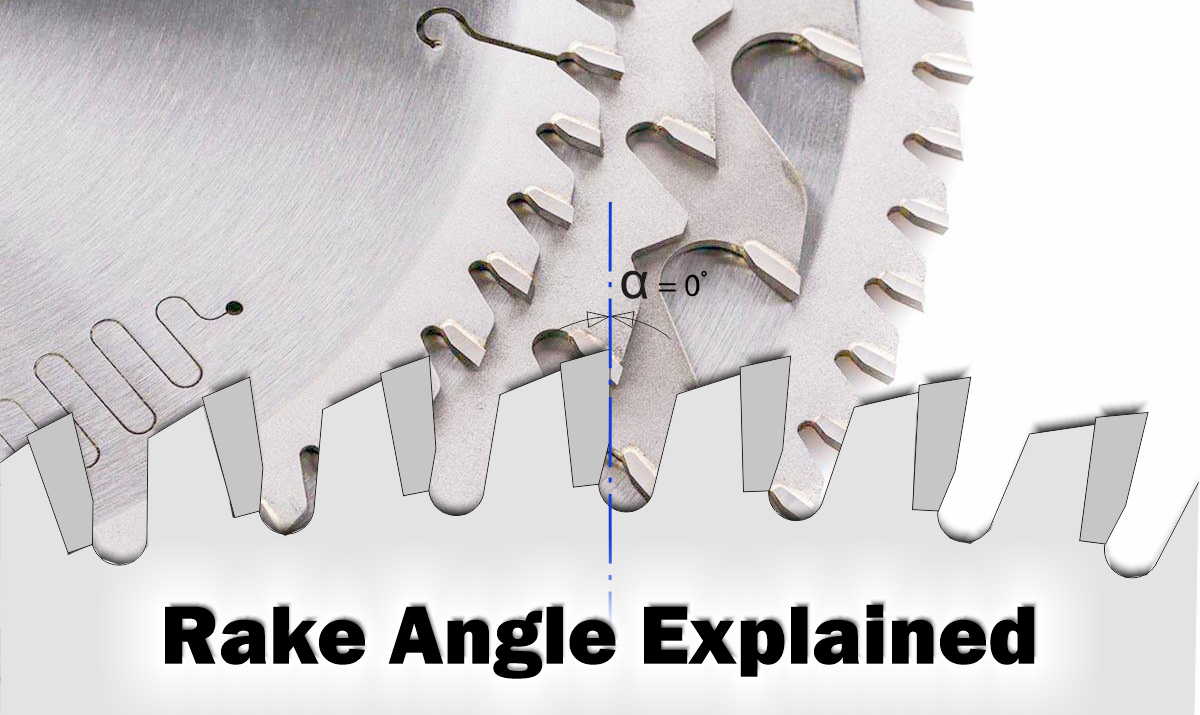

Saw Blade rake angle (hook angle) explained

The rake angle of a circular saw blade refers to the angle of the tooth face relative to a line perpendicular to the cutting surface of the blade (a radial line extending from the center of the blade). This angle plays a crucial role in determining the cutting behavior and performance of the blade.

Types of Rake Angles:

-

Positive Rake Angle:

- The tooth face leans forward (toward the direction of the cut).

- Provides an aggressive cutting action, allowing the blade to bite into the material more easily.

- Commonly used for cutting soft materials like wood and plastic, as it promotes faster, more efficient material removal.

-

Negative Rake Angle:

- The tooth face leans backward (away from the direction of the cut).

- Results in a less aggressive cut, with more controlled, smoother cutting action.

- Ideal for cutting harder materials like metals (aluminum, steel) or for precision cuts where a fine finish is required.

-

Zero Rake Angle:

- The tooth face is perpendicular to the cutting surface (a straight radial line).

- Used for more neutral cutting behavior, often found in general-purpose blades.

Positive rake angle speeds up the feed rate, delivering a quick and aggressive cut. It is ideal for cutting solid wood, plywood, laminate and MDF boards on panel saws with a scoring unit.

- α = 10°~25° - Wood

- α = 5°~15° - Chipboard, MDF, plywood, laminate, plastic

- α = 0°~10° - Chipboard, MDF, non-ferrous metal, ferrous metal

Negative rake angle is used mainly when cutting non-ferrous metals, plastic, compact boards, floating floors and Plexiglas. A tooth with negative rake angle cuts gradually into the material, slowing down the feed rate but creating a precise and smooth cut. The negative rake angle can be found on mitre saw blades in combination with an alternate top bevel. That is because of requirements for maximum versatility for cuts in solid wood, laminate or even aluminum. It is also suitable for plunge saws when cutting laminated boards without a scoring unit.

- α = -5° ~ -15° - Ferrous metals, non-ferrous metals, plastic, laminate.

Zero rake angle is commonly used for cutting Corian and thick plastic. α = 0°

- α = 0°~10°

Importance of Rake Angle:

- Cutting Efficiency: A positive rake angle makes cutting faster and easier, while a negative angle provides better control and a finer finish.

- Material Suitability: The rake angle determines what types of materials the blade is best suited for. A positive rake is better for softer materials, while a negative rake works well with harder materials and precision cutting.

- Control and Smoothness: Negative rake angles provide better control over the cut, reducing the risk of kickback and producing smoother cuts, especially in delicate or hard materials.

In summary, the rake angle of a circular saw blade is a critical factor in its cutting efficiency, material compatibility, and the quality of the cut.